We have different types of backfill materials.

In this post, we will be considering the common backfill material specification for imported soil materials.

This type of backfill material is commonly used to raise site levels to the desired elevation, to fill excavated areas which will support or retain structure, or similar pusposes.

Many things have to be considered when it comes to the technical checking of backfill material. I have tried to summarize the basic things to consider when checking backfill material for your easy review.

To proceed further, below are some points that might help you when checking backfill materials:

The Common Backfill Material Specification

In any large scale projects, the technical specification in majority of contract documents always includes the requirement of soil as backfill materials. It gives the criteria for acceptance of the fill material in complete details. Engineers are required to have a thorough review at least with the given backfill material specification to ensure compliance with the requirements.

The overused statement about the backfill material requirement which is always mentioned in a specification is:

The fill must be suitable materials.

Suitable materials are selected fill that is free from all debris, any deleterious or organic materials, clay or mud, and surplus materials other than approved by engineer.

What to Check?

Many things have to be considered when it comes to the careful checking of soil as backfill materials. Please be guided below:

a) The source of material. It is essential to identify the source of backfill material to ensure that the material being checked and brought to the laboratory was taken from the actual materials which will be used at the construction site. This details can usually be checked through available records such as material approval sheet (MAS), test reports, and delivery notes if coming from the approved supplier. The source of the backfill material must be clearly indicated and matched with all available records related to it.

b) The content of soluble matters. The backfill material must not contain any soluble components or substances such as chloride and sulphates. As per general specification, a good backfill materials must have a chloride and sulphate content not exceeding 0.05% and 1.2 gm per liter respectively.

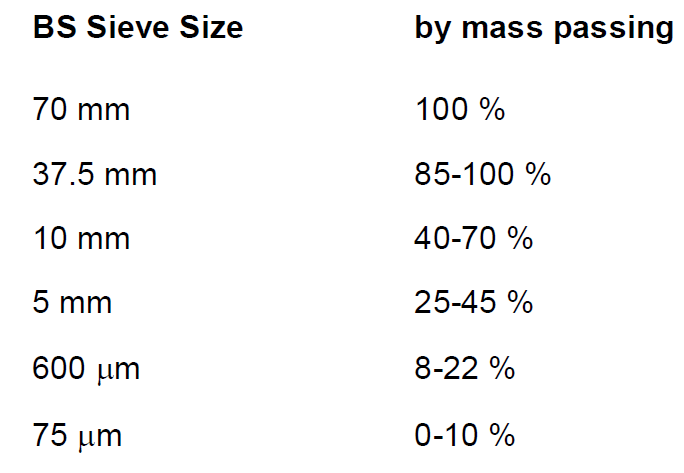

c) Grain Size Distribution. The backfill material shall be sand and gravel mixtures of appropriate grading and must not contain swelling components such as clay or organic matters. Depending upon types of backfill materials, specification are available for the reference of engineer. Meanwhile, below figure 1.0 shows sample requirement for grain or particle size distribution of backfill materials as per British Standard.

Figure 1.0.

d) The maximum dry density and the optimum moisture content. These two items always come together as they are related to each other (see definition below). They are essential in determining the degree of compaction of backfilling works being executed at site.

As an overview with actual backfilling activities, layer by layer of compaction is being conducted at the site, then being tested to the laboratory, and can proceed upon the satisfaction of the engineer with the result of the test. The required minimum degree of compaction shall be 98% according to the Modified Proctor Density. Meanwhile, the 95% degree of compaction can be considered for raising site levels or for areas which will not support any structure. For further details, you can check in your specification the compaction procedure as it is a separate topic to discuss.

How to check?

Since we already know what are the things to be checked as mentioned above. The next question will be how to check it in the actual scenario. Sample test reports are shown below to have an idea of where are the details can be found which needs to be taken care of. Let us go one by one.

a) The source of material

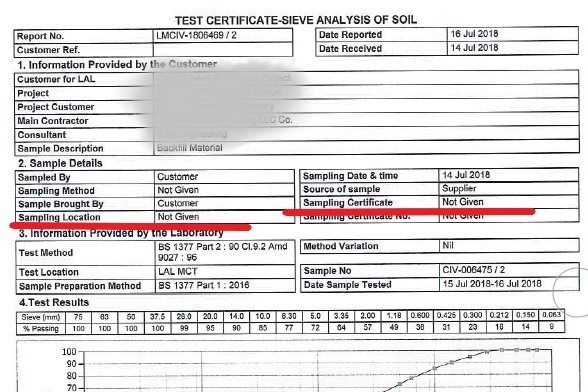

Figure 2.0.

In the above sample test report shown in figure 2.0, the source of material was not provided by the contractor. The source of material was an unidentified supplier, and the sampling location was not given. We are not sure where the backfill materials are obtained. In this case, we can let the contractor resubmit another record indicating all the necessary details.

b) Content of soluble matters.

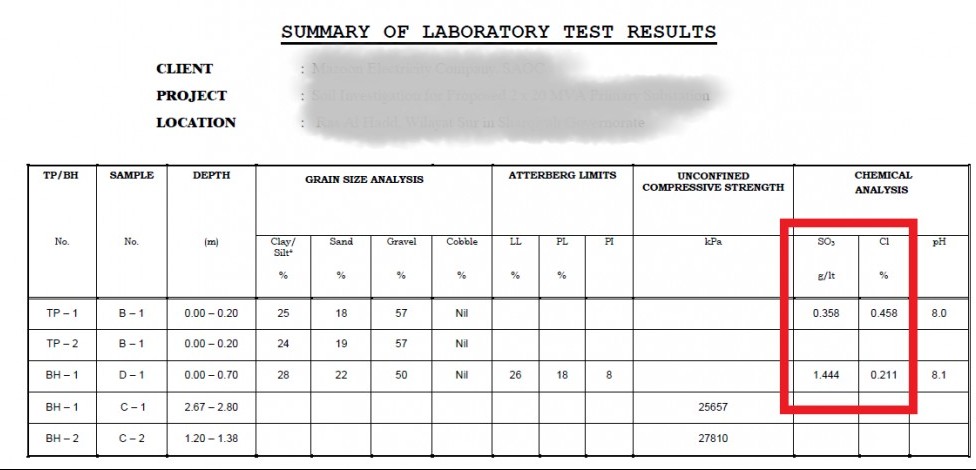

Figure 3.0.

The chloride and sulphate content shown in above sample test reports (figure 3.0) exceeds the tolerance mentioned in above specification for chloride and sulphate content. If this soil was taken from the excavated area of constructions site, we could come up with the conclusion to avoid re-using the materials due to its high content of soluble chemicals.

c) Grain size distribution

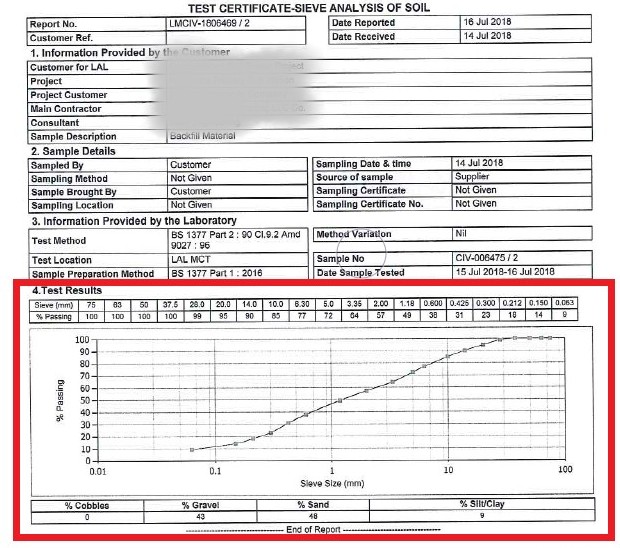

Figure 4.0

The grain size distribution can be checked by just merely comparing the result of the test reports with the specification. If the sieve size is not available, you can assume the percent passing by linear interpolation.

d) The maximum dry density and the optimum moisture content.

Figure 5.0.

Sample test report for determination of maximum dry density and optimum moisture content is shown in above figure 5.0. These results will be used to determine the degree of compaction which will be shown in a separate test report as describe earlier.

Basic Definition

- Imported soil material, fill, fill material – terms used to indicate backfill materials (also with different types).

- Technical specification – a document which is part of the contract that describes the requirements that a project or a work must meet or pass.

- Material approval sheet – a document showing the description of the materials, its supplier, and manufacturer, with a technical data sheet and other details that are submitted to the client or client representative for approval.

- Maximum Dry Density and Optimum Moisture Content– the most compact soil achieved in the laboratory at a given moisture content. The density of that compacted soil is the maximum dry density. The optimum moisture content is the corresponding amount of water added into that soil until it reaches the maximum dry density.

Always Check the Specification.

Check your specification if there are any details not covered in this post. Always remember that in various projects, there are different types, applications, considerations, or even local requirements regarding backfilling materials. It varies from a particular place to another place.

So if you will be assigned to check backfill materials, this post will be helpful to you. Meanwhile, you can then dig deeper into your specifications for details.

By the way, thank you for visiting my website. If you have something interesting to share regarding this post, feel free to drop it in the comment box below.

What an amazing article. So much information here and its great.

Just a question, because I am not familiar with the construction world. Are there any health risks at all to exposure to backfill?

Hi Patty! Thanks for visiting my website. The backfill or fill I am referring in my post is just a soil material used in construction.

Hello

which specifications you used whats the name and what number?

best,

Hello Aula,

We are using BS 1377 and AASHTO. In addition, I compiled various specs from various projects that I have.

This post seems to be a good one for backfill material and has all the paperwork to go along with it. I’m not used to checking backfill material this must be for bigger jobs or particular states. In home building, we just dig the footers pour them and start the foundation.

Hi Fred! Thanks for visiting my website. Appreciate it.

Thanks for the article! What tests determine the material type, if it is suitable ? Meaning how do you know if it has too much loam or clay?

Liked this post. Was much informative regarding the material for backfill. But i have 2questions first one is people often use waste materials like dead mortar and debris in the backfill is it really advisable to use those. And secondly is it accepted to do backfill in water lagging areas, or we need to perform de-watering before starting of the fill. Please suggest.

Hello Ajay,

1. It is not advisable to mix waste materials in your soil for backfilling.

2. Yes. You need to perform de-watering prior to start backfilling. This blog generally tackles only for backfilling under normal condition.

Thank you.

hello sir, good article. But what quality of water shall be used for backfilling-compacting purpose? this important data not mentioned.

there should be parameters of water quality mentioned. for foundation backfilling and for surface backfilling

The excavator hired for our home project back filled large rock against our basement foundation walls. He used the native material (granite) that was hammered out to dig our foundation. The size ranges from a few inches in diameter to several feet in diameter. There is no dirt or soil mixed in. What problems might we expect from this? What can we do to remedy this, or must we dig it all out and replace it with the correct materials? Thank you.

Hi Mr. William,

The mass of solid used as a base for the foundation such as your granite materials is called a hardcore bed. In selecting hardcore bed materials, you have to consider the quality (must be chemically inert), and shape and size (considering drainage, capillary action, and freezing). The bed must be well-compacted and must have the correct thickness. You can ask your hired excavator his experience or basis on this kind of work. And if he is qualified enough, then it must be okay.

the passing sieve #200 should be 0-10 % as you mentioned above, what is happened if you use for example 10-20 % passing #200

with keep P.I. less than 40%. The backfill material still granular soil 80% coarse grain soil.

thank you

Thanks for pointing out that the materials used for foundation backfilling should be approved by an engineer. I’d like to get some repairs done for one of my properties because it has some foundation problems that need attention right away. I can imagine that I will need to spend an entire weekend overseeing this kind of project.

Hi Alice,

You’re welcome.

Hello FAIS

I enjoyed reading your actual experiences, I have some experience and I know how challenging it is for starters to know about these staff. to say something based on record since that is all matters.

Please Write more on weekly or monthly basis as you are comfortable.

Hi Birhanu,

Thank you very much. I will try my best to post weekly.

Hi, Thanks for this insightful post.

Two things:

Frstly,someone suggested you mentioned the quality of water tobe used during the actual backfilling process (compaction), beacuse the backfill materials (soils) should have a tolerance of solubles (Chloride and sulphate). Please shine light on the quality of water, if you haven’t. Thanks!

Secondly, does the source or borrowed site of the backfill required any field testing such as density tests – Sand Cone replacement test ,etc. if yes, could you please give requirement(s) of each test as per the BS and AASHTO standards.

Hello Sir,

1. We are using potable water.

2. Note that we are referring only to the imported backfilling material here. Before deciding if the imported backfilling material is suitable for use, tests must be obtained. The common tests are those I enumerated in this post.

Hello Fais, thanks for your timely response.

Thank you for sharing this informative post about backfill material specifications. Your emphasis on the importance of material selection for retaining walls is particularly insightful. It’s fascinating how different materials can affect the overall stability and drainage of the structure.

I appreciated your breakdown of the physical properties to consider, such as grain size and moisture content. These factors play a crucial role in preventing issues like erosion and settlement over time. Additionally, I’d love to know your thoughts on the environmental impact of various backfill materials. Are there specific sustainable options you recommend that balance performance and eco-friendliness?