The concrete pouring guide that we will be discussing here is about checking ready-mix concrete records. We will be giving you some important notes about ready-mix concrete pouring at the end of this post as well.

Concrete is one of the basic materials being used in construction industry. The approval of this material requires careful checking to ensure quality and conformity with the design requirements as well as standards.

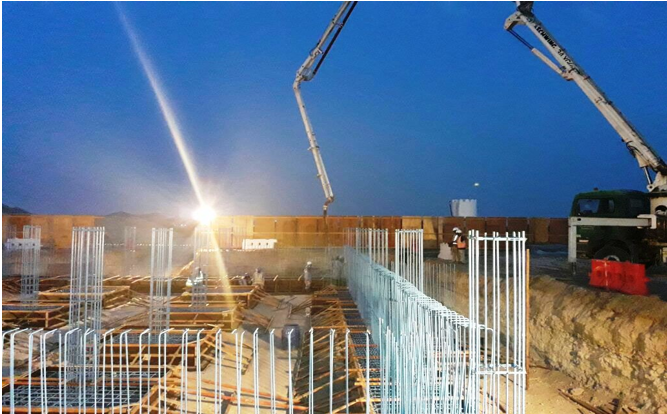

Ready-mix concrete is widely used concrete material in construction because of its variety of advantages. Companies tend to save significant time and energy when using ready-mix concrete especially supplied by a reputable ready-mix concrete supplier.

Here, without further ado, I will be giving you a list of things that need to be considered in your ready mix concrete pouring records.

Here, without further ado, I will be giving you a list of things that need to be considered in your ready mix concrete pouring records.

What are the information that must be available in a particular ready-mix concrete delivery note?

What are the things that need to be checked at the site during concrete pouring?

Checking the Delivery Note

We have to ensure that all required information must be available in the delivery note of the ready-mix concrete supplied to the site or project.

Check your previous ready-mix delivery note if all the following pieces of information can be found at least. This is not necessarily in the same order.

- The name of the ready-mix supplier

- The serial number of the delivery note

- The delivery date

- Truck number

- Complete name of the contractor

- Complete name of the contract or name of the project

- Ready-mix concrete specified workability (the result of the slump test)

- The shade temperature

- Grade of concrete

- Cement type and source

- Source of the aggregates

- The nominal maximum size of the aggregates

- The water-cement ratio

- Time of loading from the ready mix plant

- Time of departure from the ready mix plant

- The arrival time of the truck at the placing area

- The departure time of the truck

- The complete time of the discharge

- Notes or remarks that truck was checked and free from impurities

What to Check at Site?

In addition to the above-required information, the following has to be obtained, witnessed and recorded at the site as well.

- Slump test in situ for each load or truck

- The temperature of the ready-mix concrete upon the truck arrival (for each load or truck)

- The quantity being delivered (or approximate quantity)

- Arrival time interval of trucks

- The obtained number of concrete cubes or cylinder samples to be used for compressive strength test (to ensure an adequate number of samples)

- The exact location and the structure in which a specific load was to be poured

Notes

Furthermore, I would like to add on this topic some important notes related to ready-mix concrete.

- The ready-mix concrete supplier must be carefully evaluated and approved by the engineer or client representative, and it must be officially written. All the materials used in ready-mix concrete must comply with the specification. The resources for manufacturing and delivery must be sufficient to ensure appropriate and timely completion.

- The contractor shall agree with the engineer or client representative the following:

- details of the equipment (operating and stand-by)

- method statement (plan, positioning, pour sequence, number of pumps, quality control, safety and risk assessment, factors that might affect pouring, etc.)

- The specification of following below shall also be considered for ready-mix concrete. We will try to tackle these topics in another post:

- sampling

- trial mixing

- testing and quality of concrete

- The delivery note of ready-mix concrete must be encoded or computer generated.

- Copy of every delivery note must be provided to the site inspector at the site.

- All copies of the delivery note must be attached to the request for inspection and submitted officially to engineers, or client’s representative.

- The available standard for ready-mix concrete is BS 5328. You can also check the conformity of the ready-mix concrete with the mentioned standard.

- The number of revolution of the drum of the concrete mixer must be recorded by an automatic device.

- The amount of water in the ready-mix concrete shall not exceed over the maximum value allowed by the mix design.

- Slump test to be performed at the site must be in conformity with BS 1881.

- The water tank of every truck must always be full upon arrival at the site.

- The load must be rejected in any case the result of the slump is exceeding beyond the acceptable value.

- Daily temperature (maximum and minimum) shall be recorded including the wet bulb temperature.

- Water is not allowed to be added to the concrete mix at the site.

What is the meaning of …?

Concrete Pouring – also known as concrete or ready-mix casting, placing, or merely concreting.

Ready-mix Concrete – also spelled as “ready mix concrete” by others. It is the fresh concrete that is being mixed or produced in a plant known as the batch plant.

Delivery Note – a paper (or document) indicating pieces of information about the material being delivered at site.

Slump test – a test being performed at the site or laboratory for fresh concrete. It being conducted to determine the consistency of fresh concrete in relation to its final setting. It is also being conducted to determine the workability of the fresh concrete.

In situ – at the actual site location

Reference

BS 5328 – Specification for the Procedures to be used in Producing and Transporting Concrete

Ready-mix Concrete Topics

Ready-mix concrete is really a broad topic. Hope that in this topic (checking ready-mix concrete pouring records), you have obtained some basic yet essential knowledge for you to confidently proceed with the checking.

I will be trying to post more about the concrete pouring guide topics.

Hope that you found this post helpful, especially for those beginners or fresh graduates who are looking for good reference about this topic. Meanwhile, I would recommend you to read more about standards if you want to dig further technically.

If you have something to share regarding ready-mix concrete topics, I am more than happy to see it in the comments section below.

Please check also my post about Mortar for Block Work Checklist.

This has been quite informative! I have a rough knowledge regarding building/construction – going through an interior design/architecture program a few years back taught me nothing is ever as easy or simple as it seems. There are always more variables and considerations with any project than you would expect!

The glossary of terms you provided is most helpful.

So, at a construction site, is it the civil engineer who makes sure all the items you have listed are “checked off” and everything is verified and in place before the concrete is poured? Is there anyone else to assist or double check before the pouring starts? And if there are items not “checked off” what to do next?

Hi Susan! Thank you for reading my post.

For your first question, yes. In many construction projects, inspectors are being assigned to monitor or check the pouring at the site to ensure that everything is in place. Those inspectors are usually civil engineers (quality control/quality assurance engineer).

For your second question, the inspectors are coming from both sides (contractor and consultant) to witness the pouring and to certify whatever records or information that might be obtained during pouring.

And finally, if there are items which are not complying with requirements, depending upon the degree of non-conformance, the pouring activities can be either rejected or stopped.

Hi there.

My husband owns his own construction and remodeling company. I will be certain to tell him about your website and add your link to his phone.

Thanks for this helpful information.

All the best.

Thank you Wendi!

This is great, thank you.

It is so awesome that you have such a knowledge about this and you’re willing to share it.

I learned so much from reading your article and look forward to what else I can learn from your site.

Thanks!

Thank you Kahlua Gordin!

It’s important to know what kind of cement you would be using on a construction project since there are different kinds that exist. There’s a ready-mix kind of cement available which can provide advantages when used in building up walls, a floor or even helping in landscaping a garden. If I had the chance to use ready-mix cement I would want to make sure that I wouldn’t be making too many mistakes when applying it to the surface I would be working on.

After reading this entire blog post, I appreciate your efforts for providing us such an useful information about ready mix concrete pouring measures and about readymix concrete suppliers reputation etc. But I would like to mention one thing before purchasing concrete mix i.,e quality certificate from respected government.

I agree that you need to think about the water-cement ratio when you’re getting concrete. That’s very important if you want to get it right. Too much or too little water will weaken it for sure.

Thanks for ypur tips. I hope it will help me in future. Really appreciate! Keep it up

It was interesting to know that a ready mix concrete is a fresh concrete mixed or assembled in a plant known as the batch plant. My friend told me that their current project requires ready mix concrete. I think it’s best for them to partner with a company that offers complete concrete services.

I like your concrete tips. I need to pour a new driveway. I’ll have to hire a contractor to help me.

Thanks for the tip about how it’s important to also look for the proper documentation when planning to get a small load ready-mix concrete delivery service. I’d like to know more about that kind of cement because I’m interested in starting the construction of my new home soon. Having a good provider of concrete will be essential for that.

Thanks for the reminder that it’s important to also be meticulous about the quality of the concrete when planning to get concrete delivery services. I’m interested in looking for a good service like that because I’m thinking about having a larger cemented area in front of my home. That will help a lot in making the place not muddy after a rain.

I like that you talked about companies being able to save time and energy when they use ready-mix concrete from a reputable supplier. I will share this information with my husband so that we can choose the type of residential concrete mix for the construction of our driveway. And it means that we might have our driveway constructed as soon as possible because of those materials.