When we say masonry, the common materials that we can think of are clay blocks, calcium silicate bricks, or concrete blocks joined together by a cement paste mixed with fine aggregates or mortar.

Actually, we have different types of masonry building materials!

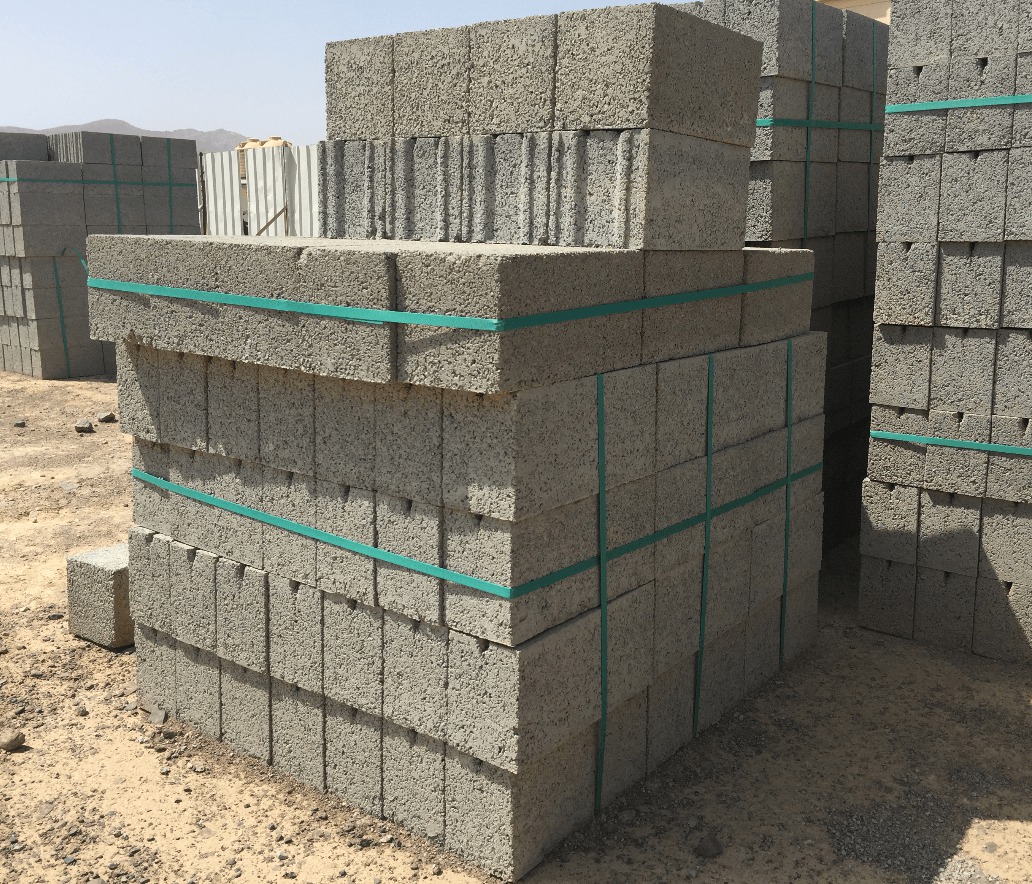

In this post, we will be looking on a specific masonry building material which is the concrete block or also called in general term as concrete masonry unit.

Let us start with the reference code.

Reference Code for Masonry Design (British Standards)

I have read some technical specification from various contracts regarding the reference code for the use of masonry.

Upon reading some papers, I found out that two different codes are being used for masonry. First is the BS 5628 (Code of Practice for the Use of Masonry. And second is the BS EN 1996 also known as the Eurocode 6 (Design of Masonry Structures).

However, I have noticed in one specification that BS 5628 was crossed out and was corrected into BS EN 1996.

At first, I was curious about it. Can I use both reference codes? Is there any difference between the two? I was really wondering if it is acceptable to use either one of them.

As a matter of fact, I haven’t read many of those codes. I did a quick research to see the difference between the BS 5628 and the Eurocode 6.

Here is what I found with my research!

BS 5628 was one among those 55 British standards withdrawn by BSI (British Standards Institution) dated March 31, 2010, making BS EN 1996 as the dominant code for masonry design.

Therefore, it may be regarded as certain to stick with BS EN 1996.

Checking Masonry Building Materials

In this post, the focus of our checking will revolve only about concrete blocks (concrete masonry unit), its dimension, and its compressive strength. I will be discussing other details such as the checking of mortar and masonry accessories, sundry items, anchors, ties, steel rod, insulation, joints in my future post.

Concrete Blocks (Concrete Masonry Unit)

1. Concrete Block Dimension

First, let us have the definition of terms. The terms involve here is the coordinating size and the working size. Coordinating size means the size or the dimension of a space in which a concrete block will occupy including joints (mortar) and tolerances. Meanwhile, working size means the actual size of the concrete block in which manufacturer will produce considering specified tolerances.

For a concrete block with coordinating size of 400mm long, 200mm height, and 100mm thick, the working size should be 390mm long, 190mm height, and 100mm thick.

Here is the list of common concrete block dimensions:

Coordinating Size (length x height x thickness):

- 400mm x 200mm x 200mm

- 400mm x 200mm x 150mm

- 400mm x 200mm x 100mm

Corresponding Working Size for above respectively (length x height x thickness):

- 390mm x 190mm x 200mm

- 390mm x 190mm x 150mm

- 390mm x 190mm x 100mm

Now, for you to check them, all you have to do is find the test result provided by the third party laboratory regarding concrete block dimension. If it is not available, you can ask or require your contractor to obtain them.

Upon the availability of the test, you can check if they are acceptable or not. The tolerances for working size of the block which are generally accepted are as follows:

- The length and the height tolerances must be within +3mm to -5mm.

- The thickness must be within +2mm to -2mm for any measurements.

- The thickness must be within +1.5mm to -1.5mm for the mean of 7 measurements of any one block.

2. Compressive Strength of Concrete Block

I have read various books and specifications regarding the compressive strength of the concrete block and I found the details quite technical. For those who are busy or for those who feel lazy to read lengthy specifications, here are some brief guidelines in checking the compressive strength of concrete blocks.

The compressive strength of concrete blocks will depend on the requirement specified by the designer either in the drawing or in the technical specification. Yes. Designers are specifying their requirement for the compressive strength of concrete block somewhere in the project document. We do not know whether they designed it for load-bearing or non-load-bearing structures. Who cares during construction stage! All we need is the design strength. So the next time you need to check concrete block strength, all you have to do is to browse your drawings and technical specification and look for the required compressive strength.

Meanwhile, if you still cannot find it in the drawings or in the technical specification, I will be giving you the compressive strength of concrete blocks based on the technical specification that I have read. I have read four specs, and I found the following comparison. Please note that this is applicable for both solid and hollow concrete masonry unit. Remember that all concrete blocks shall be tested according to BS 6073. They shall not be less than the compressive strength values given according to requirement.

Specification No.1

For external non-load-bearing walls:

- The average compressive strength of 10 concrete blocks: 7.5 MPa

- The lowest individual compressive strength of block: 5.6 MPa

Specification No.2

For external non-load-bearing walls:

- The average compressive strength of 10 concrete blocks: 10.5 MPa

- The lowest individual compressive strength of block: 7.5 MPa

Specification No.3

For external non-load-bearing walls and load-bearing walls:

- The average compressive strength of 10 concrete blocks: 7.0 MPa

- The lowest individual compressive strength of block: 5.6 MPa

For load-bearing walls below ground:

- The average compressive strength of 10 concrete blocks: 10.5 MPa

- The lowest individual compressive strength of block: 8.4 MPa

For internal non-load-bearing walls and roof blocks:

- The average compressive strength of 10 concrete blocks: 2.5 MPa

- The lowest individual compressive strength of block: 2.0 MPa

Specification No.4

For external and internal non-load-bearing walls:

- The average compressive strength of 10 concrete blocks: 7.0 MPa

- The lowest individual compressive strength of block: not provided

From above specification, I believe specification 1, 3, and 4 are somewhat matching each other. Meanwhile, we can say that specification 2 is quite overdesigned.

Finally, you can easily check the test report provided by the third party laboratory regarding the compressive strength of concrete blocks based on above.

It’s great you talked about the different kinds of specifications when it comes to choosing cement blocks when you’re looking to remodel your house or part of the garden to accommodate a few new things to be built on the property. One should keep in mind the size of any and all masonry blocks used since these all have different sizes and some would work better than others in certain locations, as part of a wall or part of a wall garden decor piece. If I had to use these kinds of blocks to redecorate the garden then I would make sure to check the size of the blocks I would be using as I have limited space as it is to have a large garden.